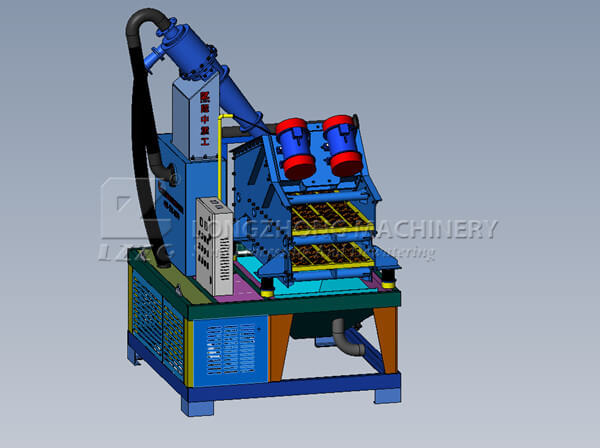

Slurry Treatment System

LZZG Slurry treatment system is widely used for slurry purifying and recycling in pile foundations of railways and highways, municipal, subway, tunnel shield, oil drilling. This equipment is increasingly becoming a necessity of civilized construction since it not only can cut down construction cost, but also can reduce the pollution of the environment.