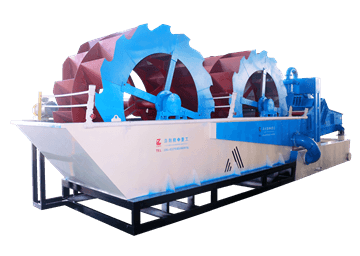

Dual Wheel Sand Washing & Recycling Machine

Dual wheel washing machine is is upgraded and developed based on the original sand washing and recycling equipment. The sand can be cleaned, dehydrated and graded twice, which will greatly reduce the content of mud and impurities and water in sand and improve the sand quality. Dual wheel sand washing machines can widely process sandstone and quartz sand, aggregate, coal, ore, tailing, etc.