Belt Filter Press

LZZG Sludge Dewatering Belt Filter Press is a common type of mechanical dewatering equipment. Which is widely used for efficient dewatering of sludge from municipal, industrial, mining and aggregaes wastewater treatment plants.

LZZG Sludge Dewatering Belt Filter Press is a common type of mechanical dewatering equipment. Which is widely used for efficient dewatering of sludge from municipal, industrial, mining and aggregaes wastewater treatment plants.

LZZG Sludge Dewatering Belt Filter Press is a common type of mechanical dewatering equipment. Which is widely used for efficient dewatering of sludge from municipal, industrial, mining and aggregaes wastewater treatment plants. Especially suitable for dewatering of tailings mud such as iron ore, copper ore, lead-zinc ore, fluorite ore, bauxite or rare earth ore; Dewatering operations such as ore dressing wastewater, sand washing mud or wash plant sludge.

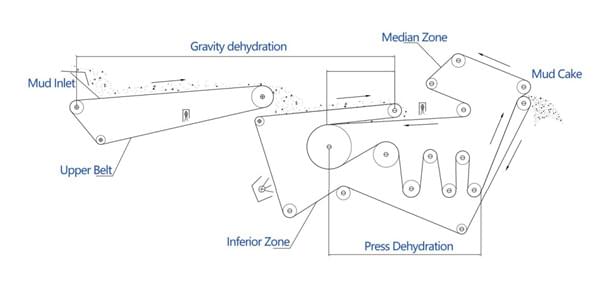

The slurry is sandwiched between two tensioned porous belts, by passing those belts through a serpentine of decreasing diameter rollers. Water is then removed from the slurry and a solid material is produced.

(1) Thickener dehydration: chemical pretreatment stage

The belt filter press has higher requirements for flocculation effect. This machine uses a unique dosing mixer to achieve rapid flocculation and achieve the best flocculation effect.

(2) Gravity dehydration: gravity drainage stage

The sludge is evenly fed into the mesh belt through the cloth bucket. The sludge runs forward with the filter belt. The free water flows into the water tank through the filter belt under the action of its own weight. The main function is to remove the free water in the sludge, so that the fluidity of the sludge is reduced and ready for further extrusion.

(3) Low/medium pressure squeezing: wedge preloading dewatering stage

After gravity dewatering, it is still difficult to meet the sludge flowability requirements of the press dewatering section. After this stage of slight extrusion dewatering, the sludge is smoothly pressed and dewatered.

(4) High pressure squeezing: the depressurization stage of the clamp press

The filter cake is repeatedly pressed and sheared around the press roll by the upper and lower filter belts. A large amount of capillary action water is removed to gradually reduce the moisture of the mud cake.

1. Belt press has an easily adjustable and variable wedge compression zone that maximizes process rate and performance.

2. Suitable for all types of organic sludge and inorganic mud, municipal WWTP sludge, pulp &paper sludge, water plant sludge.

3. The belt press is constructed with a stainless steel structure and rollers, durable for more than 10 years .

4. Low power is needed to run the belt filter presses. With long term value and ease of operation.

5. Compact footprint, 4-stage dewatering and automated operation

| Model | Capacity (t/h) | Belt Width (mm) | Belt Number (pic) | Power (kw) | Overall Size (mm) |

| DY1500 | 6-10 | 1500 | 3 | 11 | 12000*2300*3200 |

| DY2000 | 8-12 | 2000 | 3 | 11 | 12000*2800*3200 |

| DY2500 | 10-16 | 2500 | 3 | 15 | 12000*3300*3200 |

| DY3000 | 12-20 | 3000 | 3 | 15 | 12000*3800*3200 |

You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!