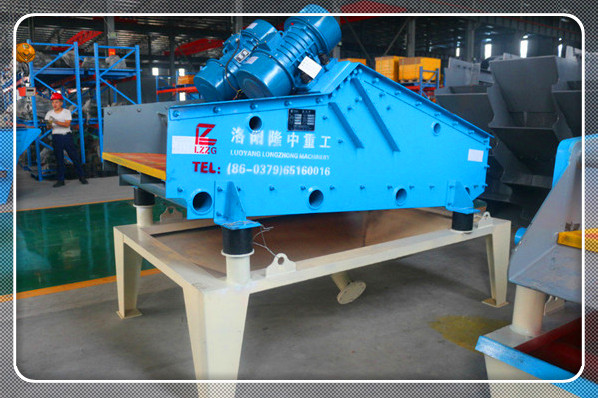

High frequency vibrating screen is used in coal washing plant

Date: Aug. 21, 2021

If you are interested in our products, Please get in contact with us .

Date: Aug. 21, 2021 Chat Line Send InquiryHigh frequency vibrating screen is used in coal washing plant

The high-frequency vibrating screen uses an electromagnetic vibrator to drive the transmission system, so that the transmission system vibrates the screen to achieve the purpose of improving the screening efficiency. It has the characteristics of simple operation, stable performance, high efficiency, low energy consumption and strong self-cleaning screen. It is widely used in industries such as mineral processing, coal, building materials, chemicals, abrasives, etc.

Ways to improve coal screening efficiency

1. Adjust the excitation current (amplitude) in order to make the sieve work under the conditions of comparative efficiency, the excitation current condition test can be done according to the nature of the ore and the operation requirements;

2. To avoid short-circuit, cover the exciter with a rubber sheet. The electromagnetic exciter and control box should be protected from water splashing: prevent short-circuit and blockage of air gaps caused by the falling of water and mineral slurry;

3. The position or angle of the screen frame should be adjusted in time. When the slurry hopper into the screen is too far, so as not to affect the separation efficiency;

4. Because the sieve has good dewatering performance, high screening efficiency, and high concentration of the amount on the screen, the slurry in the amount chute on the screen has poor fluidity, so it should be equipped with a water pipe;

5. Adjust the excitation current (amplitude) in order to make the screen work under efficient conditions. According to the nature of the ore and the requirements of the operation, the excitation current condition test can be done;

6. The position or angle of the screen frame should be adjusted in time. When the slurry hopper into the screen is too far, so as not to affect the efficiency of separation;

7. Check at any time whether the screen frame collides with the chute, etc. and whether the bolts of each part are loose;

8. Remove the sieve, and use the sieve for 1 month. Make a 180-degree U-turn to enhance the cutting effect of the sieve bar, so as to improve the efficiency of dividing J.

Send us a message

You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!